OUR CAPABILITIES

Manufacture Capabilities

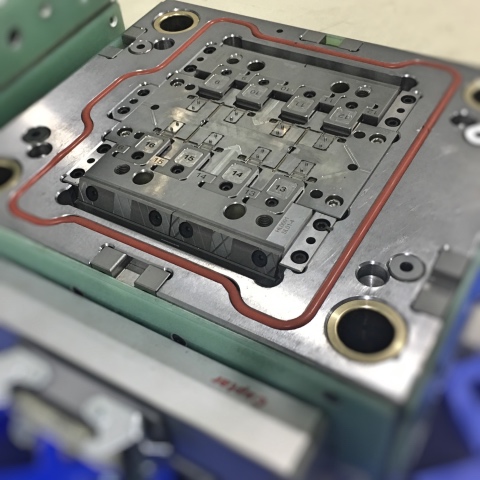

Ultra-Precision Tooling

With our state-of-the-art high-precision machines, we can achieve tooling accuracy up to 0.005mm.

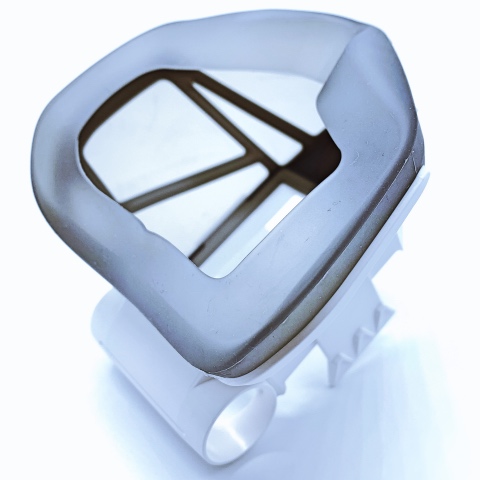

Precision Plastic Injection for Over-Molding with LSR

High-speed plastic injection machines equipped with 6-axis robot arms are capable of producing high precision plastic parts.

Precision LSR Molding

Ultra-precision LSR molding machines housed in clean production room are capable of producing all kinds of precision LSR parts and overmolded components (Plastic+LSR, Metal+LSR & LSR+LSR).

Double-Shot Injection Molding

We have 2-shot molding capability for complex parts involving Plastic+LSR & Plastic+TPU/TPE.

Spray Painting, Secondary Processes, UV Curing Process and Assembly

We offer secondary processes such as spray painting, silk screening, pad-printing, UV curing and assembly services.

TOOL ROOM

Tool Room

In-house tool room with state-of-the-art high precision machines :

- AgieCharmilles High Precision EDM

- Sodick High-Speed High Precision EDM

- Sodick Ultra-Precision Wire-Cut EDM

- Mikron HSM500 High-Speed CNC

- Makino F5 High Speed CNC

- Makino IQ300 Ultra-High Speed CNC

- Okamoto Precision Surface Grinding

PRODUCTION FACILITIES

Production Facilities & Equipment

Ultra-precision LSR injection molding & high speed plastic injection machines housed in clean production room.

-

52unitsLSR Injection Molding Machines

52unitsLSR Injection Molding Machines- Sodick 100T

- Multitech 85T

- 2KM Metering & Mixing System

- 2-Shot (Plastic + LSR) Molding Capability

- Robot-Assist Production System

-

24unitsPlastic Injection Molding Machines Equipped with 6-Axis Robot Arms

24unitsPlastic Injection Molding Machines Equipped with 6-Axis Robot Arms- Fanuc 50T

- Fanuc 100T

- Toyo 100T

- Sumitomo 100T

- Toshiba 2-Shot (Plastic+LSR) 100T

- DCM 2-Shot 200T

- DCM 2-Shot 250T

-

5XoutputHighly Automated Production Lines

5XoutputHighly Automated Production Lines- Fully automated with the integration of 6-axis robot arms

- Highly efficient & increase production output by 5X

-

Stable production output with consistent quality

- Clean production environment

SECONDARY OPERATIONS

Secondary Operations

We offer secondary process services such as spray painting, printing, UV curing and assembly.